Calibration Services defines the accuracy and quality of measurements recorded using an instrument. The results and accuracy of instrument drifts over me hence there is an ongoing need to maintain the calibration of equipment throughout its lifetime for accurate and reliable measurements.

Online Calibration of Multifuction Meter

Online Calibration of Energy Meter

Online Calibration of Ammeter & Voltmeter

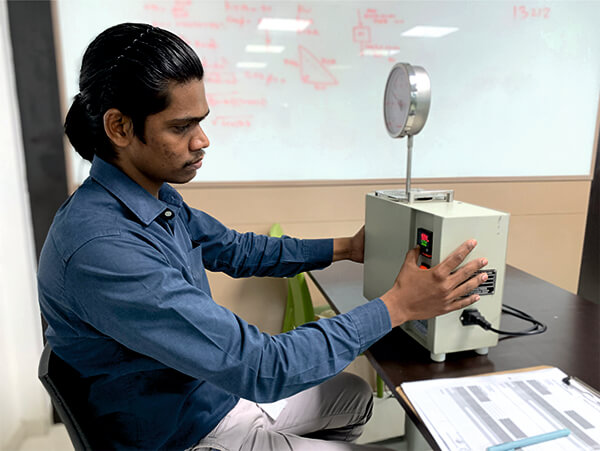

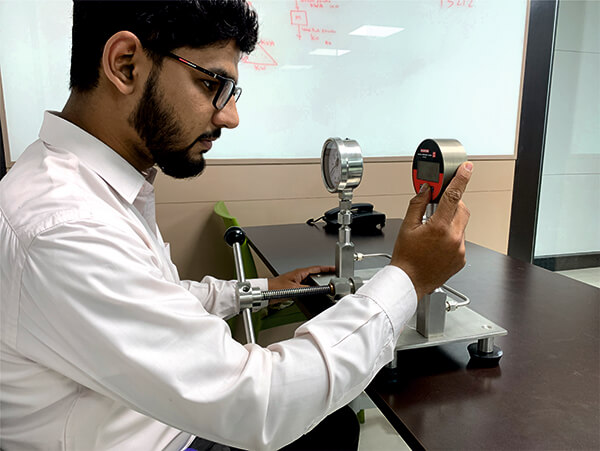

Calibration of Pressure Gauges

Calibration of Temperature Gauges

Calibration of Water Meters, etc

Calibration is the process of adjusting, comparing, or verifying the accuracy and reliability of a measuring instrument or system by comparing its measurements to a known reference or standard. It involves making necessary adjustments to the instrument to align its readings with the reference, ensuring that it provides accurate and consistent results.

The need for calibration arises from the inherent limitations and potential inaccuracies of measuring instruments over time. Factors such as wear and tear, environmental conditions, aging components, and usage can cause instruments to drift or deviate from their original calibration. Calibration helps to address these issues and ensure the reliability and accuracy of measurements. Here are some key reasons why calibration is necessary: